Potato sprout control in storage a changing landscape

Growing a healthy potato crop and proper loading into storages present only the initial steps to ensure a steady, uninterrupted supply of potatoes throughout the year.

Depending on the varietal characteristics — whether it has short, medium or long dormancy, potato tubers will last in storage without any sprout control treatments only for the duration of its dormancy period. For longer periods of storage, sprout control treatments become a necessity.

For more than 50 years, the global standard for sprout control in storage has been chlorpropham (CIPC), which was also used extensively as a pre-emergence herbicide for controlling grass weeds in many crops such as onions, carrots, soybeans, tomatoes etc. All herbicidal crop uses have since been revoked. However, CIPC’s primary use — controlling sprouting in post-harvest potatoes, continues to be available in many countries and is excellent to this day.

For CIPC applications to be effective, the first treatment should be made prophylactically, generally two to three weeks after storage loading, after the wound healing and suberization (or skin set) phases are completed. In North America, one or two applications made during the storage cycle are necessary to ensure long term sprout control.

The changing landscape

In the U.S. and Canada, CIPC was recently re-registered ensuring its availability into the near future. In contrast, the European Food Safety Authority (EFSA) concluded last year that no safe use of CIPC was feasible. Based on this conclusion, the European Union did not renew CIPC approval for potato post-harvest uses beyond Jan. 8, 2020 in the 28 EU-member countries (including the UK) and the grace period for use expires on Oct. 8, 2020.

The CIPC potato tolerance (also called Maximum Residue Limit or MRL) will also be reduced in the next few months from 10ppm to 0.01ppm. Discussions among stakeholders and regulators are ongoing to establish a temporary MRL (tMRL) between 0.3 to 0.5ppm to accommodate inadvertent residues resulting from CIPC-contaminated storages. On a longer time-frame, the CIPC CODEX MRLs (currently set at 30 ppm) could also be reduced significantly in line with EFSA’s dietary risk calculations and affect future international import and export of potatoes among countries.

Due to the long-standing regulatory pressure relating to CIPC residues, extensive research to discover new sprout control products globally has been underway for some time, and the EU non-renewal has brought about fresh urgency to look at emerging products and design suitable sprout control strategies.

- New potato varieties. Driven by changing consumer preferences in the USA and Canada, newer varieties developed specifically for the fresh market (such as whites, yellows and other thin-skinned types) have gained market share, especially for fresh packs. These varieties generally have short to medium dormancies and demand more attention agronomically and in storage — to ensure sustained deliveries of quality, sprout-free potatoes.

- Potato harvest and storage conditions. Changing weather patterns have led to higher soil temperatures during harvest. This situation can lead to rapid break-down of latent dormancy, which results in early sprouting — sometimes even in the field. Factors which contribute to sprout control challenges in storage such as fluctuating storage temperatures in older, leaky structures with poor building design or faulty ventilation, refrigeration or humidification systems, presence of diseases and improper timing of applications should also be addressed in addition to choice of sprout control products.

The sprout control toolbox

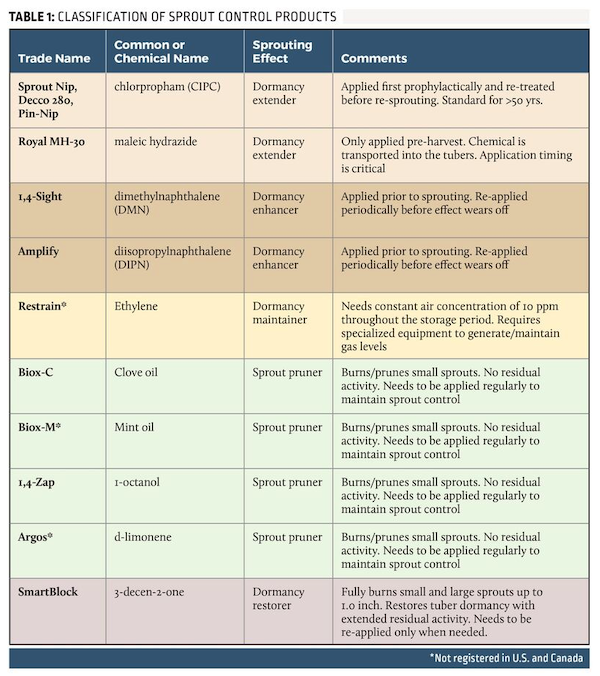

The potato tuber is basically an underground stem with a built-in dormancy period. The length of dormancy is directly dependent on the storage temperature. After the dormancy period expires, developing sprouts need to be controlled to preserve tuber integrity. As described in Table 1 (below), sprout control can be achieved by (a) extending dormancy (b) enhancing dormancy (c) maintaining dormancy (d) pruning or “burning” sprouts or (d) restoring dormancy.

Understanding the effect of each of these sprout control agents, along with the correct timing and dosage is necessary to formulate a cogent strategy for designing the best sprout control program. All products are applied often through custom hot fogging equipment at temperatures exceeding 350°F, except for Royal MH-30 which is applied as a spray (pre-harvest) and ethylene gas whose concentration is continuously maintained inside the storage environment with the aid of an ethylene gas canister or generator.

Sprout control for fresh pack and processing potatoes

Fresh pack potatoes have a very low tolerance for any visible sprouts and are typically stored at lower temperatures (40 to 45°F). As such, controlling sprouts presents less of a challenge, and all products presented in Table 1 (above) can offer acceptable control depending on the desired period of storage and frequency of re-applications.

Potatoes treated with Royal MH-30 (maleic hydrazide) prior to harvest extend the natural dormancy period specific to that variety and sprout control treatments can be timed or delayed accordingly and it can be a valuable tool to incorporate into any sprout control program.

Some, such as the sprout pruners (Biox-C and others) offer only short-term control of around four weeks for each treatment and therefore these will need to be re-applied on a regular basis to keep the tubers sprout-free. Tubers stored under ethylene gas (Restrain) as well as all tubers treated with sprout pruners do not have adequate shelf life and tend to re-sprout quickly either at the grocery store or at home.

CIPC (a dormancy extender) and the dimethyl or isopropyl naphthalenes (1,4-Sight and Amplify) are — both dormancy enhancers, and need to be first applied before tubers break dormancy and re-applied mid-season and late season as the chemical effect starts to wear off. Both naphthalene products do not control (or “burn”) the sprouts and therefore need to be applied first as prophylactic treatments and are often combined with CIPC to boost their effectiveness.

SmartBlock (3-decen-2-one, a dormancy restorer) is best applied at or after tuber dormancy break to take advantage of the variety’s natural dormancy period. It works by attacking only the developing meristematic sprout tissue, restoring dormancy and providing long-term residual sprout control. For tubers exhibiting small to medium sprouts later in the season, the sprouts can be “burned” and longer sprouts (up to 1 inch) can be fully desiccated. Such withered sprouts fall off the tuber during pack out operations.

For potatoes destined for the processing market, the storage temperature generally ranges from 48 to 52°F. Although there is some tolerance for visible sprouts, sprout-free tubers are preferred. Storage temperature in this range need to be maintained otherwise the cold-induced sweetening effect will result in darker chip or french fry colors but sprout control presents a significant challenge. The products which can provide sustained long-term control for processing potatoes are CIPC, the naphthalenes and SmartBlock. Combining specific products based on their sprout control effects can be a useful approach for achieving the desired sprout control. Thermal fogging mixtures with CIPC (such as low rate CIPC+SmartBlock) is one solution for achieving overall lower CIPC usage, better chemical re-distribution inside the potato storage and obtaining sprout “burn” of any existing sprouts.

The changing landscape for potato sprout control presents new opportunities as well as challenges. The global potato supply chain companies are actively looking for new approaches for replacing CIPC. The good news is that we now have several tools to create integrated solutions. However, understanding the strength and weaknesses of each product and then formulating optimal sprout control strategies unique to each variety and storage situations will be critical to successfully deliver high quality, sprout-free potatoes and healthy profits to the farmers in the future.

— John A. Immaraju, Ph.D., is the Senior Director of Product Commercialization at AMVAC Chemical Corporation and can be reached at [email protected]. This article is part of a series coordinated with the Potato Association of America (PAA).